Lupine

Publishers- Latest Trends in Textile and Fashion Designing

Abstract

During high speed sewing, needle thread is subjected to dynamic

loading, inertia forces, friction and repeated tensile stresses at

tremendous rates. The value of these stresses depends upon stitching

speed, sewing thread tension, stitch length and sewing thread

properties. These parameters affect the tensile properties of sewing

threads adversely, leading to loss in seam strength. In this study,

the effect of various parameters lubrication (%), stitch density, the

number of fabric layers and stitching speed on tensile properties

of sewing thread has been studied using Box- Behnken design. Contrary to

the popular belief, loss in tenacity increases as stitching

speed increases. 4% lubrication (%) is suggested to get minimum tenacity

loss (%).

Keywords: Breaking Elongation; Initial Modulus; Sewing Thread; Tenacity

Keywords: Breaking Elongation; Initial Modulus; Sewing Thread; Tenacity

Introduction

In the apparel industry, the sewing process is one of the

most critical processes in the determination of productivity

and quality of the finished garment Anand [1]. The production

rate of garment industry has increased significantly because of

technological development. Due to increase in the machine speed,

rapid modification in fabric characteristics just as fabric type, the

degree of finishing has brought more stringent requirements on the

characteristics and performance of threads used in garment industry

Gersak and Knez [2]. It is well established that manufacturers can

improve the quality of garments by using better sewing thread,

improved machinery, better garment design and trained personnel.

However, use of better-quality sewing thread appears to be easiest

and least expensive Rengasamy [3]. Seam strength and seam

performances are dependent on the strength of the threads. So,

high strength of sewing thread is a basic requirement for good

sewability Midha [4]. If thread becomes weaker during sewing

process and after getting incorporated into the seam it results into

lower seam strength.

The other tensile properties such as breaking elongation and

initial modulus also influence the quality of seam in different

ways. Therefore, it becomes very important to know the sewing

mechanism and extent of loss in tensile properties during sewing.

During the sewing process in a high-speed sewing machine,

the thread is subjected to complicated kinematic and dynamic

conditions. Sewing thread is subjected to friction, tensile, bending,

compressive, shear, and surface stresses. These stresses act on

the thread frequently for an adequately prolonged period of time;

sewing thread passes more than 50-80 times through the fabric, the

needle eye, and bobbin case mechanism before getting incorporated

into the seam Ukponmwan [5], Midha [6]. As a result, both the

sewing thread and the yarns in the fabric get abraded during the

sewing process. Number of researchers observed that there could

be 30-40% strength reduction in the cotton thread after sewing

Sundaresan [7], Sundaresan [8]. Different studies confirm that

structural damages in the thread, results due to the displacement

of the plies, twist alterations at specific locations and the surface

fibres get pulled out of the structure. The damages are mostly

concentrated at the interlocking portion of the needle thread in

the stitch, where maximum tension, bending and thread-thread

abrasion takes place Sundaresan [7], Rudolf and Gersak [9]. Most

of the researchers focused on estimating the amount of damage in

the sewing threads during sewing and identified the various reason

for that damage viz. structural damage, dynamic loading, and

thermal damage. However, limited studies are available on the role

of different parameters affecting the loss in thread strength after

sewing. A careful selection of these parameters can help in reducing

the damage in sewing threads during sewing. In this paper, the effect of

process parameters like lubrication (%), stitch density,

the number of fabric layers and machine speed has been studied

on changes in the tensile properties (tenacity, breaking elongation,

and initial modulus) of the needle threads during sewing.

The other tensile properties such as breaking elongation and initial modulus also influence the quality of seam in different ways. Therefore, it becomes very important to know the sewing mechanism and extent of loss in tensile properties during sewing. During the sewing process in a high-speed sewing machine, the thread is subjected to complicated kinematic and dynamic conditions. Sewing thread is subjected to friction, tensile, bending, compressive, shear, and surface stresses. These stresses act on the thread frequently for an adequately prolonged period of time; sewing thread passes more than 50-80 times through the fabric, the needle eye, and bobbin case mechanism before getting incorporated into the seam Ukponmwan [5], Midha [6]. As a result, both the sewing thread and the yarns in the fabric get abraded during the sewing process. Number of researchers observed that there could be 30-40% strength reduction in the cotton thread after sewing Sundaresan [7], Sundaresan [8]. Different studies confirm that structural damages in the thread, results due to the displacement of the plies, twist alterations at specific locations and the surface fibres get pulled out of the structure. The damages are mostly concentrated at the interlocking portion of the needle thread in the stitch, where maximum tension, bending and thread-thread abrasion takes place Sundaresan [7], Rudolf and Gersak [9]. Most of the researchers focused on estimating the amount of damage in the sewing threads during sewing and identified the various reason for that damage viz. structural damage, dynamic loading, and thermal damage. However, limited studies are available on the role of different parameters affecting the loss in thread strength after sewing. A careful selection of these parameters can help in reducing the damage in sewing threads during sewing. In this paper, the effect of process parameters like lubrication (%), stitch density, the number of fabric layers and machine speed has been studied on changes in the tensile properties (tenacity, breaking elongation, and initial modulus) of the needle threads during sewing.

Materials and Methods

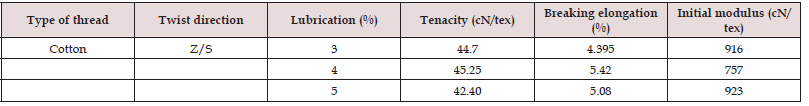

Cotton staple spun threads of 37tex with silicon and wax finish

are used in the study. The threads are two and ply and shows 314

turns per meter. The physical properties of the sewing threads are

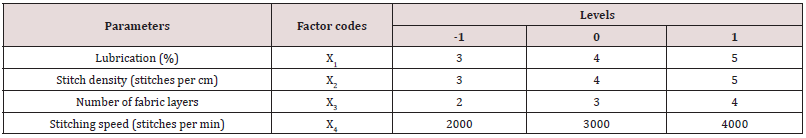

shown in Table 1. The effect of various process parameters, viz.

lubrication (%), number of fabric layers, stitch density and stitching

speed on the tensile properties of sewing threads is studied by

measuring the tensile properties of the threads before and after

sewing at three different levels of these parameters, according to

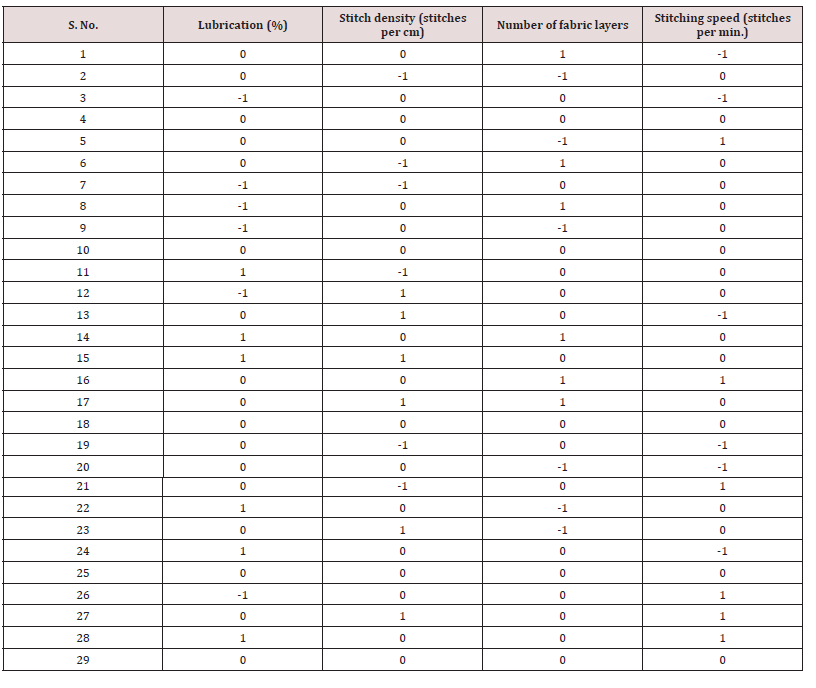

Box-Behnken experimental design (Tables 2-3). Brother Industrial

lockstitch sewing machine is run at different speeds for preparation

of samples using rib knitted fabric. Tensile testing of the needle

threads before and after sewing is done at a gauge length of 250mm

on Universal Testing Machine as per ASTM D 2256. Thirty tests are

carried out for individual sample and the error is found to be less

than 4% at 95% confidence limit. The change in tensile properties

is calculated using equation 1.

Box Behnken Design.

Loss(%)=(Tensile property before sewing-Tensile property

after sewing)/(Tensile property before sewing)×100

In order to study the individual and interactive effect of each

parameter on tensile properties, response surface regression

equations are developed for loss in tensile properties at different

levels of lubrication (%), number of fabric layers, stitch density and

stitching speed by backward elimination method.

Box Behnken Design.

Loss(%)=(Tensile property before sewing-Tensile property after sewing)/(Tensile property before sewing)×100

In order to study the individual and interactive effect of each parameter on tensile properties, response surface regression equations are developed for loss in tensile properties at different levels of lubrication (%), number of fabric layers, stitch density and stitching speed by backward elimination method.

Results and Discussion

Table 4 shows the tenacity loss, breaking elongation loss

and initial modulus loss after sewing at different levels of the

parameters. The average of 30 readings for each sample is analyzed

to create regression equation on statistical software STATISTICA

8. The linear and polynomial equations are tried along with the

interaction of the parameters, at 95% confidence level. The bestfit

equations for tenacity loss, breaking elongation loss and initial

modulus loss are generated. The regression equations have a very

good R2 value and can be used to study the effect of different

parameters on tenacity loss, elongation loss and initial modulus

loss.

*-ve sign indicates gain in initial modulus.

*-ve sign indicates gain in initial modulus.

Tenacity loss and breaking elongation loss

Analysis of variance shows lubrication %, stitch density and

stitching speed has a significant effect on the tenacity loss (Table

5), whereas number of fabric layers does not show any significant

effect on the tenacity loss. However, number of fabric layers and

stitching speed has an interactive effect on tenacity loss. Breaking

elongation is affected by number of fabric layers and machine speed.

Lubrication % and stitch density does not show any significant

effect on breaking elongation loss (Table 5).

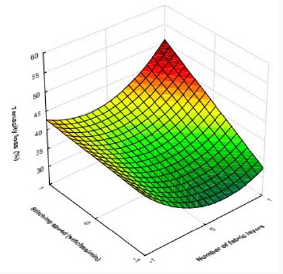

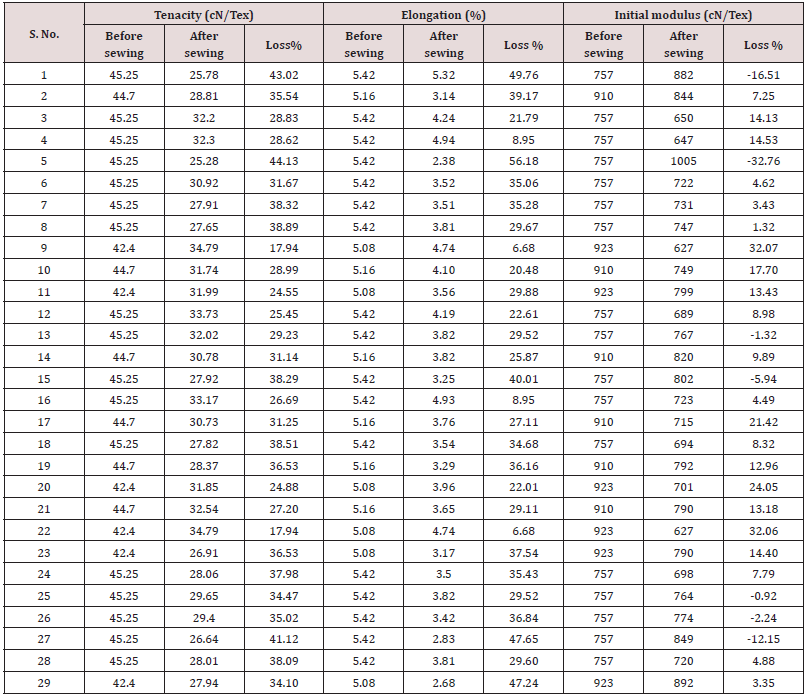

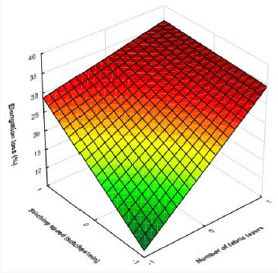

Figure 1 shows the effect of lubrication% and stitch density on

tenacity loss (%) of thread during sewing. It is observed that, as

the lubrication % increases, the loss in tenacity first decreases and

then increases. This is because lubricants provide a surface coating

to sewing threads that protect it from the abrasive actions during

its interaction with machine parts, fabric and bobbin thread. But

further increase in lubrication ratio causes decreases in fibre to

fibre friction which leads to slippage during the tensile loading and

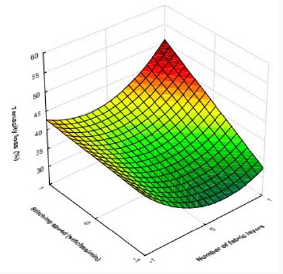

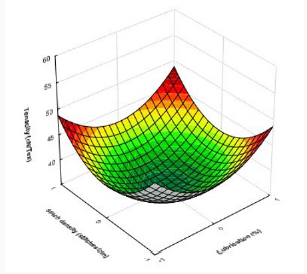

therefore reflects as tenacity loss (%). Lubrication % does not show

any significant effect on the elongation loss% as shown in Figure

2. This may be due to the increased slippage of fibres at higher

lubrication, leading to increase in breaking elongation, which

compensates for the loss in breaking elongation during the sewing

process.

Further, it is observed that tenacity loss first decreases and

then increases with increase in stitch density as shown in Figure 1.

Increased level of stitch density causes a decrease in stitch length,

thereby decreasing thread consumption per stitch. The stress level

experienced by the thread during pulling of the thread from the

spool during stitch tightening is reduced and therefore, the threads

experience a lower level of damage. At higher stitch density, the

thread also experiences a higher number of dynamic loading and

abrasive cycles before getting incorporated into the fabric, leading

to more damage to the thread. As the stitch density increased

further, the effect of a higher number of loading and abrasive cycles

outweighs the effect of decreased stress levels, and therefore the

thread experiences higher tenacity loss Midha and Gupta [10].

Stitch density does not show any effect on the elongation loss of

sewing threads as shown in Figure 2.

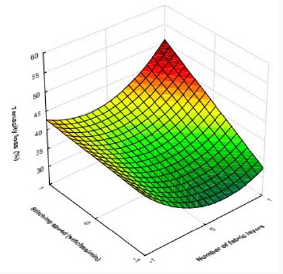

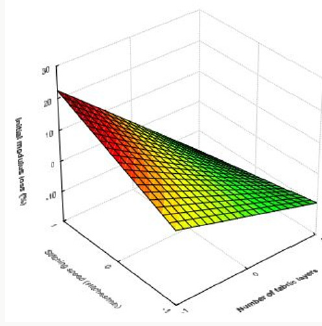

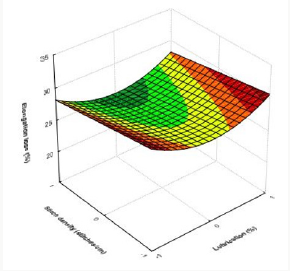

Figure 3 shows the effect of stitching speed and number of

fabric layers on tenacity loss of sewing thread. It is observed that

number of fabric layers does not show a notable effect on tenacity

loss (%) as per analysis of variance (Table 5). However, number of

fabric layers and stitching speed have an interactive effect on the

tenacity loss (Figure 3).

Figure 3: Effect of number of fabric layers and stitching

speed on tenacity loss (%) of sewing thread.

Figure 1 shows the effect of lubrication% and stitch density on tenacity loss (%) of thread during sewing. It is observed that, as the lubrication % increases, the loss in tenacity first decreases and then increases. This is because lubricants provide a surface coating to sewing threads that protect it from the abrasive actions during its interaction with machine parts, fabric and bobbin thread. But further increase in lubrication ratio causes decreases in fibre to fibre friction which leads to slippage during the tensile loading and therefore reflects as tenacity loss (%). Lubrication % does not show any significant effect on the elongation loss% as shown in Figure 2. This may be due to the increased slippage of fibres at higher lubrication, leading to increase in breaking elongation, which compensates for the loss in breaking elongation during the sewing process.

Further, it is observed that tenacity loss first decreases and then increases with increase in stitch density as shown in Figure 1. Increased level of stitch density causes a decrease in stitch length, thereby decreasing thread consumption per stitch. The stress level experienced by the thread during pulling of the thread from the spool during stitch tightening is reduced and therefore, the threads experience a lower level of damage. At higher stitch density, the thread also experiences a higher number of dynamic loading and abrasive cycles before getting incorporated into the fabric, leading to more damage to the thread. As the stitch density increased further, the effect of a higher number of loading and abrasive cycles outweighs the effect of decreased stress levels, and therefore the thread experiences higher tenacity loss Midha and Gupta [10]. Stitch density does not show any effect on the elongation loss of sewing threads as shown in Figure 2.

Figure 3 shows the effect of stitching speed and number of fabric layers on tenacity loss of sewing thread. It is observed that number of fabric layers does not show a notable effect on tenacity loss (%) as per analysis of variance (Table 5). However, number of fabric layers and stitching speed have an interactive effect on the tenacity loss (Figure 3).

Figure 3: Effect of number of fabric layers and stitching

speed on tenacity loss (%) of sewing thread.

Effect of number of fabric layers and stitching speed on tenacity loss (%) of sewing thread

Figure 3 At lower stitching speed, as the number of fabric layers

increase, tenacity loss decreases. But at higher machine speed as

the number of fabric layers increase, a sharp increase in tenacity

loss is observed. As number of fabric layers increase, the thread

consumption per stitch increases. Increased thread consumption

per stitch means the needle thread is subjected to a lower number

of loading cycles before getting incorporated into the seam; which

in turn leads to lower damage to the sewing thread. However, as the

number of fabric layers increases further, the needle penetration

force increases and sewing thread is subjected to higher abrasive

damage. Higher abrasive damage of cotton fibers outweighs the

effect of lower number of loading cycles, and therefore an increase

in tenacity loss (%) is observed Midha [6].

Similarly, as stitching speed increases, at lower number of

fabric layers, the marginal increase in tenacity loss is observed.

But tenacity loss significantly increases, as the stitching speed

increases, at higher number of fabric layers. As the stitching speed

and number of fabric layers increase, higher penetration forces and

higher frequency causes increase in needle temperature, which is

expected to damage the synthetic threads. However, in the present

study cotton thread has been used. As stitching speed increases,

needle thread has more frequent interaction with various stresses

imposed during sewing and therefore visco-elastic characteristics

of the thread are affected. After dynamic loading of the thread

at higher levels of tighening tension, the sewing thread is held

retracted for stress recovery for a very short time and therefore is

not able to attain stress relaxation. Due to this, stress in the sewing

thread increases as the number of cycles increase. Consequently,

extension of lateral molecular bonds and molecular slippage results

in the breakage of these bonds.

Figure 4 shows the effect of stitching speed and number of fabric

layers on elongation loss (%). Number of fabric layers and stitching

speed have an interactive effect on the elongation loss (Table 5).

At lower stitching speed, as the number of fabric layers increase,

elongation loss increases. But at higher stitching speed as the

number of fabric layers increase, no significant elongation loss (%)

is observed. But, when both the parameters considered separately

then they have notable effect on elongation loss (Figure 4) and

increasing trend is observed. As the number of layers increases,

abrasion between needle thread and fabric also increases. Due to

this surface of the sewing thread get damaged ultimately causing

higher elongation loss (%). The same trend is observed for stitching

speed. As machine speed increases, due to frequent contact of

needle thread with fabric, fibres get pulled out from thread surface.

So, elongation loss increases.

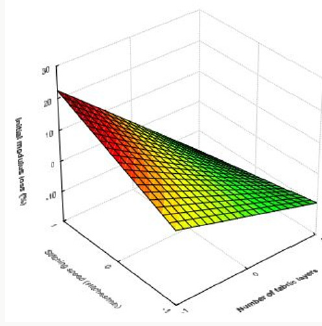

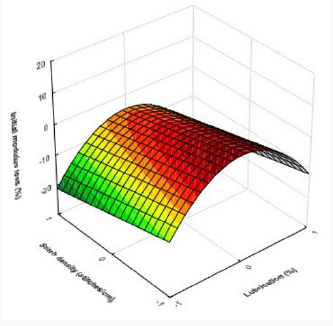

Figure 5 shows the effect of lubrication on the loss of initial

modulus. As lubrication % increases from 3 to 4%, there is an

increase in initial modulus loss after sewing. Because silicone oil

lubricates the fiber surface and causes twist to unravel, leading

to pullout of fibres from the structure of the thread. At higher

lubrication %, initial modulus loss decreases. Initial modulus is

known to increase after the dynamic loading of threads, whereas

it decreases during the passage through the needle and fabric, and

during bobbin thread interaction. The abrasive effect outweighs

the increase during the dynamic loading, leading to fall in initial

modulus after sewing. At higher lubrication %, the abrasive damage

is expected to reduce and therefore a small increase in initial

modulus due to dynamic loading, causes lower initial modulus loss.

The results are similar to what has been observed by the previous

researchers [6,8,10]. Further, it is observed from the analysis of

variance that stitch density does not show any significant influence

over initial modulus loss%.

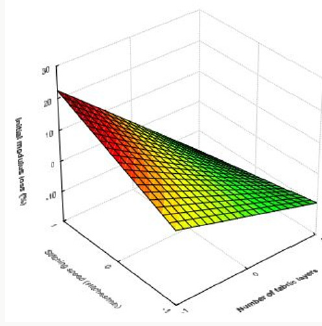

Figure 6: Effect of number of fabric layers and stitching

speed on initial modulus loss (%) of sewing thread.

Figure 6 shows the effect of stitching speed and number of

fabric layers on initial modulus loss of sewing thread. The effect of

stitching speed on the initial modulus loss % is observed to have

an interactive effect with the number of fabric layers (Table 5). At

lower stitching speed, as number of fabric layers increase initial

modulus loss slightly decreases. But at higher stitching speed, a

significant drop in initial modulus loss takes place. The loss in

initial modulus occurs due to the non-contribution of surface fibres

to thread tension. Number of abrasive cycles cause fraying of thread

surface and pull out of fibres, leading to a loss in initial modulus of

threads. As the number of fabric layers increases, the number of

abrasive cycles decrease, but the stress levels to which the thread

is exposed during tightening is higher. With an increase in machine

speed, surface of the thread gets damaged and fibres from the

surface come out and that contribute to the initial modulus loss %.

Similarly, as stitching speed increases, at lower number of fabric layers, the marginal increase in tenacity loss is observed. But tenacity loss significantly increases, as the stitching speed increases, at higher number of fabric layers. As the stitching speed and number of fabric layers increase, higher penetration forces and higher frequency causes increase in needle temperature, which is expected to damage the synthetic threads. However, in the present study cotton thread has been used. As stitching speed increases, needle thread has more frequent interaction with various stresses imposed during sewing and therefore visco-elastic characteristics of the thread are affected. After dynamic loading of the thread at higher levels of tighening tension, the sewing thread is held retracted for stress recovery for a very short time and therefore is not able to attain stress relaxation. Due to this, stress in the sewing thread increases as the number of cycles increase. Consequently, extension of lateral molecular bonds and molecular slippage results in the breakage of these bonds.

Figure 4 shows the effect of stitching speed and number of fabric layers on elongation loss (%). Number of fabric layers and stitching speed have an interactive effect on the elongation loss (Table 5). At lower stitching speed, as the number of fabric layers increase, elongation loss increases. But at higher stitching speed as the number of fabric layers increase, no significant elongation loss (%) is observed. But, when both the parameters considered separately then they have notable effect on elongation loss (Figure 4) and increasing trend is observed. As the number of layers increases, abrasion between needle thread and fabric also increases. Due to this surface of the sewing thread get damaged ultimately causing higher elongation loss (%). The same trend is observed for stitching speed. As machine speed increases, due to frequent contact of needle thread with fabric, fibres get pulled out from thread surface. So, elongation loss increases.

Figure 5 shows the effect of lubrication on the loss of initial modulus. As lubrication % increases from 3 to 4%, there is an increase in initial modulus loss after sewing. Because silicone oil lubricates the fiber surface and causes twist to unravel, leading to pullout of fibres from the structure of the thread. At higher lubrication %, initial modulus loss decreases. Initial modulus is known to increase after the dynamic loading of threads, whereas it decreases during the passage through the needle and fabric, and during bobbin thread interaction. The abrasive effect outweighs the increase during the dynamic loading, leading to fall in initial modulus after sewing. At higher lubrication %, the abrasive damage is expected to reduce and therefore a small increase in initial modulus due to dynamic loading, causes lower initial modulus loss. The results are similar to what has been observed by the previous researchers [6,8,10]. Further, it is observed from the analysis of variance that stitch density does not show any significant influence over initial modulus loss%.

Figure 6: Effect of number of fabric layers and stitching

speed on initial modulus loss (%) of sewing thread.

Figure 6 shows the effect of stitching speed and number of

fabric layers on initial modulus loss of sewing thread. The effect of

stitching speed on the initial modulus loss % is observed to have

an interactive effect with the number of fabric layers (Table 5). At

lower stitching speed, as number of fabric layers increase initial

modulus loss slightly decreases. But at higher stitching speed, a

significant drop in initial modulus loss takes place. The loss in

initial modulus occurs due to the non-contribution of surface fibres

to thread tension. Number of abrasive cycles cause fraying of thread

surface and pull out of fibres, leading to a loss in initial modulus of

threads. As the number of fabric layers increases, the number of

abrasive cycles decrease, but the stress levels to which the thread

is exposed during tightening is higher. With an increase in machine

speed, surface of the thread gets damaged and fibres from the

surface come out and that contribute to the initial modulus loss %.

Conclusion

In the present investigation, the effect of lubrication %, number

of fabric layers, stitch density and stitching speed on the loss in

tensile properties of cotton sewing threads after sewing has been

studied. The regression equations for various responses agree

well with the experimental data as indicated by higher values of

coefficient of determination. It is observed that lubrication %, stitch

density and stitching speed has a significant effect on the tenacity

loss. Elongation loss % is affected by lubrication % and number

of fabric layers. Initial modulus is affected by all the parameters

except stitch density. Number of fabric layers and stitching speed

have an interactive effect on loss of all tensile properties.

For more Lupine

Publishers Open Access Journals Please visit our

website:

For more Open Access Latest Trends in Textile and Fashion Designing Journal articles Please Click Here:

Follow on Linkedin : https://www.linkedin.com/company/lupinepublishers

Follow on Twitter : https://twitter.com/lupine_online

For more Lupine

Publishers Open Access Journals Please visit our

website:

For more Open Access Latest Trends in Textile and Fashion Designing Journal articles Please Click Here:

Follow on Linkedin : https://www.linkedin.com/company/lupinepublishers

Follow on Twitter : https://twitter.com/lupine_online

No comments:

Post a Comment